| Min. Order: | 1 |

| Price: | 10-15 |

| Port: | China |

| Place of Origin: | Ningbo,China |

| Settlement Method: | L/C |

| Transportation Method: | Shipping |

| Company: | Hangzhou Santiway International Co. Ltd |

| Contacts: | Ms.Hong Shen |

| Mail: | iris@santiway.com |

| Phone: | 18606529086 |

| Website: | http://www.santiway.com |

| PV: | 275 |

Supplier

Hangzhou Santiway International Co. Ltd

| Model Number | STW-Sandwich Panel-1 | ||||

|---|---|---|---|---|---|

| Brand Name | stw | ||||

| origin | China | ||||

| Small Orders | Accepted | ||||

Design technical data:

Wind load: 0.6kN/sqm

Roof dead load: 0.35kN/sqm

Roof live load: 0.5kN/sqm

Earthquake intensity: 8 grades

Location temperature: 25 to 45°C

Function: common use for roofing tiles

Advantages:

Lightweight

Heat-insulation and good sound insulation

Good durability and waterproof

Fireproof: A

Easy installation

Features:

Certification: ISO 9001:2000

Technical: hot galvanized steel then color coated

Lightweight: enough to reduce building experience

Good durability: with special coating, the warranty of the color steel

Sheet: 20-30 years

Fireproof: panels are fireproof and meets the relevant standards completely

Sound insulation: up to 40-50 decibels

Import processing equipment and modernized production line

Strict quality inspection five inspection procedures

Special competence of personnel going to post after professional skill check

High-class efficiency:

Processing capacity two large-scale manufacturing workshop and design

Material supply rapidness, smooth, with adequate spare parts

Management capacity rich experience

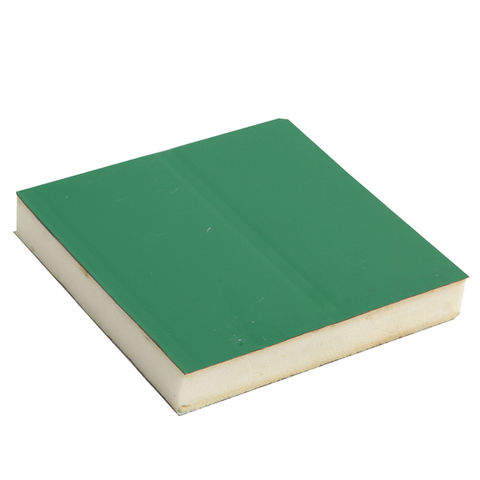

Polyurethane VS. EPS (Expanded polystyrene)

Polyurethane is a relatively new product, roughly around 15 years. EPS has been with us for around 25 years. Polyurethane was produced to replace the shortfalls of expanded polystyrene. Below you will see a detailed difference between polyurethane, and expanded polystyrene.

R- Value | Polyurethane is highest rated insulation in the world. You will find it in most all of your refrigerators, freezers, and even in your personal carry out coolers. Per inch of insulation it has no equal. The walk in coolers and freezers for use thought the country are made of polyurethane. EPS has a value of R-2 to R-5 per inch. Polyurethane has an R- 7 to R-8 per inch. |

| Manufacturing | Probably the biggest difference between polyurethane and EPS is in the manufacturing of these panels. Both products use OSB for covering both sides of their foam, but here is where the similarity ends. In the bonding of the foam the actual polyurethane is used as bonding agent to the OSB itself. Polyurethane is one of the best glues used in the industry today. Some manufactures of OSB and plywood use polyurethane gives both an excellent R value and the strongest bond in the industry. EPS panels use glue spread on both sides of OSB, and then the OSB is matched together with the EPS, and mechanically held in place and under pressure until the glue is dried. |

| Moisture resistance | With all the problems of mold and mildew, moisture resistance is today a very important factor. Polyurethane has one of lowest moisture permeability ratings of any product manufactured for the building industry today. The permeane rating on polyurethane is 1.2. The permeance rating on EPS is 2.0 to 5.0 |

| This difference in a high humidity area would warran another moisture barrier for EPS panels. In calculating R- values, some EPS manufactures use these additional moisture barriers in there calculations. | |

| Fire resistance | The polyurethane is a UL class 1 rated foam. This means that polyurethane is not a source for fire. On its'own, polyurethane will not burn. When left on it's own, it will extinguish it self. A Class 1 rating is the highest rating a building product can obtain. Also, polyurethane is a thermal -set plastic. THIS means, that it will not melt. Polyurethane is not affected until temperatures reach 120 degrees and at that time it will only char. EPS on the other hand is not a thermal -set plastic and will begin to soften at termperatures of 70 degree. Polyurethane has a distinct advantage. |

| Density | The density of a product will determine the strength of it. EPS has a density of 1lb. The polyurethane has a density of 2.2lb. |

| Chemical restance | Polyurethane is resistant to most counter chemicals. EPS react violently to petroleum based products. PL 400 and liquid nail will literally burn thru EPS. |

| From our experience, we feel that the investment made equals the quality of product made. We believe that there is no comparison between polyurethane panels and EPS. | |

| Wall panel thickness | 30mm,40mm,50mm,60mm,75mm,100mm | ||

| Sandwich panel effect width | 950mm,900mm | ||

| Matel sheet thickness | 0.4mm-0.8mm | ||

| Matel sheet top coating | 18-25um |

| FOB Port | Ningbo | ||||

|---|---|---|---|---|---|

| Weight per Unit | 5.0 Metric Tonnes | ||||

| Export Carton Dimensions L/W/H | 5.85 x 2.23 x 2.15 Meters | ||||

| Lead Time | 15–35 days | ||||

|---|---|---|---|---|---|

| Dimensions per Unit | 1.0 x 0.5 x 0.6 Meters | ||||

| Units per Export Carton | 25.0 | ||||

| Export Carton Weight | 27 Metric Tonnes | ||||

- Asia

- Australasia

- Central/South America

- Eastern Europe

- Mid East/Africa

- North America

- Western Europe

Other products from this company

China Factory Color Coated Fireproof Wall and Roof Material Sandwich Panel

Min Order: 100

China Factory Color Coated Fireproof Wall and Roof Material Sandwich Panel

Min Order: 100

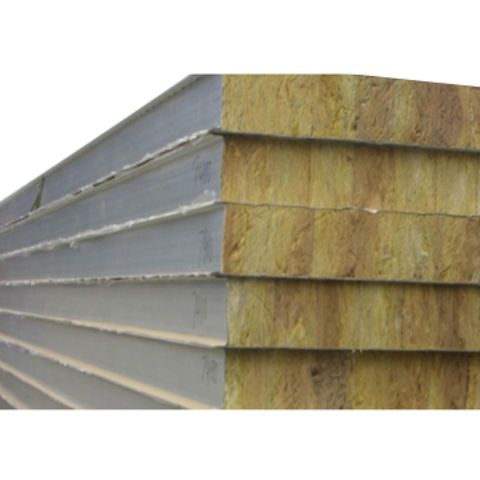

Fireproof rock wool sandwich panel

Min Order: 100

EPS/PU/Rock Wool Sandwich Panel

Min Order: 100

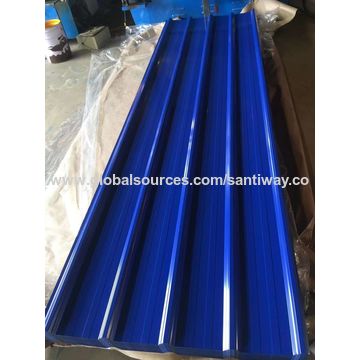

Corrugated Steel Sheet for Roofing steel Sheet Porcelain Tile

Min Order: 100

Tile Effect Roofing Sheet with Zinc Coating, Aluminum Sheet

Min Order: 100What do you want to buy or inquire, please search directly

Scan uses

small programs

© 1999-2022 宁波搜点网络科技有限公司 All rights reserved. 浙ICP备19009040号

Intellectual Property Protection - Privacy Policy - Terms of Use

法律声明免责声明:本站系所有用户均可免费发布信息,本站所有信息由各公司自行发布,请在交易前确认真实合法性,本站不承担任何法律责任,如有侵权请联系我们客服电话:0574-87020551